TONGUE AND GROOVE FLOOR BOARD

DryBloc® TG4 18/22mm

Suitable for flooring applications, including wet underfloor heating (UFH), acoustic/ soundproof flooring, dry screed panel systems, and tiling

DryBloc® TG4 is a tongue and groove floor board which has been designed as the utopian floorboard, for any flooring applications such as wet underfloor heating (UFH), acoustic soundproof flooring, dry screed panel systems, and tiling.

High Density Overlay Board as a wet underfloor heating (UFH), acoustic soundproof flooring, dry screed panel systems, and tiling

Description

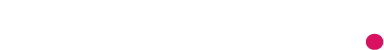

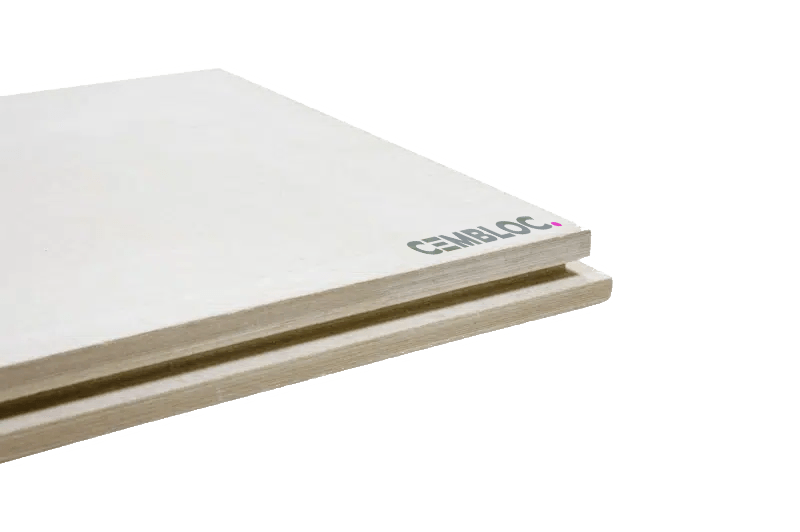

CEMBLOC® DryBloc® TG4 is available in thicknesses 18mm, 20mm and 22mm. The DryBloc® TG4 is an A1 fire rated solution. CEMBLOC® DryBloc® TG4 tongue and groove floor board (T&G) profile, reinforced cement fibre board, reinforced by natural minerals on both sides boasting an impressive loading capacity of up to 7kN/m² (max weight test rig could test - based on DryBloc® TG4/22). These dry-fit screed replacement panels at only 18mm , 20mm and 22mm thick offer minimal floor height and save on drying times when compared to traditional screeds.

DryBloc® TG4 is exceptionally unique as it offers an outstanding thermal conductivity value 0.216 W/mK when used in conjunction with underfloor heating systems. DryBloc® TG4's high density provides excellent airborne sound performance through many types of separating floors. It is a high performing multipurpose building board that’s designed purposely to provide fireproof, acoustic and waterproof protection, with very high dimensional stability which makes it a high performance alternative to Gypsum and Cement Particle for any construction type.

DryBloc® TG4 is superior flooring board with exceptional dimensional stability of (<0.19%) compared to alternatives such as chipboard, gypsum fibre and cement bonded particle board.

Our professional team are here to help you with any questions.

| Product | SKU | Length | Width | Thickness | Weight | Edge Detail |

|---|---|---|---|---|---|---|

| DryBloc® TG4/18 | CEM6006 | 1200mm | 600mm | 18mm | 17.50kg | TG4 |

| DryBloc® TG4/20 | CEM6007 | 1200mm | 600mm | 20mm | 19.44kg | TG4 |

| DryBloc® TG4/22 | CEM6008 | 1200mm | 600mm | 22mm | 21.38kg | TG4 |

Distributed Loading Capacity:

| Joist Spacing (ctrs) | 400mm | 400mm | 600mm | 600mm |

|---|---|---|---|---|

| Recommendations | DryBloc® TG4/18-22mm | DryBloc® TG4/18-22mm | DryBloc® TG4/22mm | DryBloc® TG4/22mm |

| Thickness | UDL | CL | UDL | CL |

| 18mm | 13.70 kN/m² | 3.50 kN | 3.90 kN/m² | 1.55 kN |

| 1397.01 kg/m² | 356.9 kg | 397.68 kg/m² | 158.06 kg | |

| 20mm | 17.50 kN/m² | 4.10 kN | 5.40 kN/m² | 2.10 kN |

| 1784.50 kg/m² | 418.08 kg | 550.64 kg/m² | 214.14 kg | |

| 22mm | 21.30 kN/m² | 4.70 kN | 7.00 kN/m² | 2.70 kN |

| 2171.99 kg/m² | 479.26 kg | 713.80 kg/m² | 275.32 kg |

Note:

- Concentrated load is applied over an area of 300mm x 300mm.

- Allowable maximum deflection is limited to l/250 of joist spacing.

- UDL, Uniform distributed load.

- CL, Continuous load.

- For spans above 450mm we recommend DryBloc® TG4/22, for spans below 450mm, DryBloc® TG4/18-20mm are more than suitable

Support for Your Project

Have a technical advisor get in touch to discuss your needs and work out a suitable, effective solution for you. Get a quote, our experts are here to help you find the best solution for your project. Call us today:

+44 (0) 208 050 5302

or send an email to

support@cembloc.com

Advantages Of Use.

- Provides durable protection for sub-construction systems, extending their lifespan.

- Resists dirt buildup, contributing to low-maintenance requirements.

- Manufactured without harmful substances and is environmentally friendly.

- Guaranteed asbestos-free for safe use in various environments.

- Classified as A1 for fire safety, meaning it is non-combustible.

- Does not emit toxic gases when exposed to fire.

- Highly resistant to moisture and water exposure, reducing risk of warping or swelling.

- UV-resistant, withstanding prolonged sunlight exposure with minimal degradation.

- Dimensionally stable, resisting cracking from seasonal temperature changes.

- Allows for straightforward installation and modifications.

- Can be precisely cut with suitable tools, such as carbide-tipped saws.

- Functions as a dry finishing material, eliminating the need for wet screed and associated drying times.

- Protects and extends the life of insulation materials in thermal and acoustic systems.

- Exhibits extremely high dimensional stability (<0.19%) compared to chipboard, gypsum, and cement particle boards.

- Moisture-resistant, effectively reducing water absorption compared to traditional wood and gypsum-based boards.

- Odourless and does not release toxic gases.

- Highly resistant to impact, making it suitable for high-traffic areas.

- Resistant to biological and chemical waste exposure, maintaining structural integrity.

- Lightweight and easy to transport.

- Insect-proof, non-putrescible, and resistant to mold growth.

- Versatile for a wide range of building applications.

- Compatible with insulation materials of any desired thickness.

- Provides smooth, precise cuts for fine detailing in installations.

- Offers very high impact resistance, significantly exceeding that of gypsum-based boards.

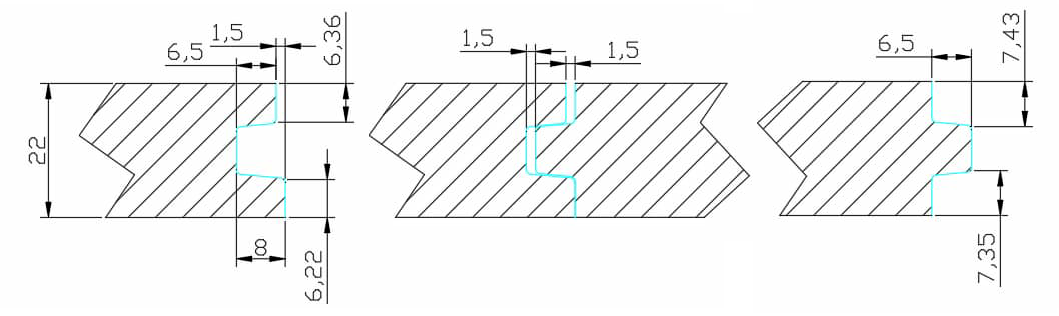

Profile.

Our suggestion is to place the smooth side facing up. Make sure to maintain consistency in the orientation of each board during installation.

Areas Of Use.

- Compatibility with Routed Insulation for Underfloor Heating: This cement fibre board can be used in conjunction with routed insulation for Underfloor Heating (UFH) applications, offering a thermal conductivity of 0.216 W/mK.

- Versatile Flooring Options: It is suitable for installation on both timber and steel joisted floors, providing flexibility for various construction needs.

- Integration with Metsec Style Decking: The board can also be incorporated into a buildup on Metsec-style decking, enhancing the overall structural performance.

- Joist Spacing and Thickness Recommendations: This cement fibre board is designed to span joists at a spacing of 450 mm or less when using 18 mm thickness. For joist spacings above 450 mm, we recommend using the 22 mm thickness to ensure optimal support and stability, while also being mindful of the overall loading capacity.

- Wet Screed Replacement: Ideal for use as a replacement for traditional wet screed applications, offering enhanced durability and moisture resistance.

- Compatible with Beam and Block Constructions: Suitable for integration into beam and block flooring systems, providing structural support and stability.

- Access Flooring Solutions: Effectively used in access flooring systems, allowing for easy installation and maintenance of utilities.

- Raised Terrace Applications: Appropriate for raised terrace constructions, delivering a robust surface that withstands environmental elements.

- Mezzanine Flooring: Can be utilised in mezzanine flooring applications

- Replacement for Traditional Timber Floorboards; Serves as an excellent alternative to traditional timber floorboards, offering improved moisture resistance and longevity.

Downloads