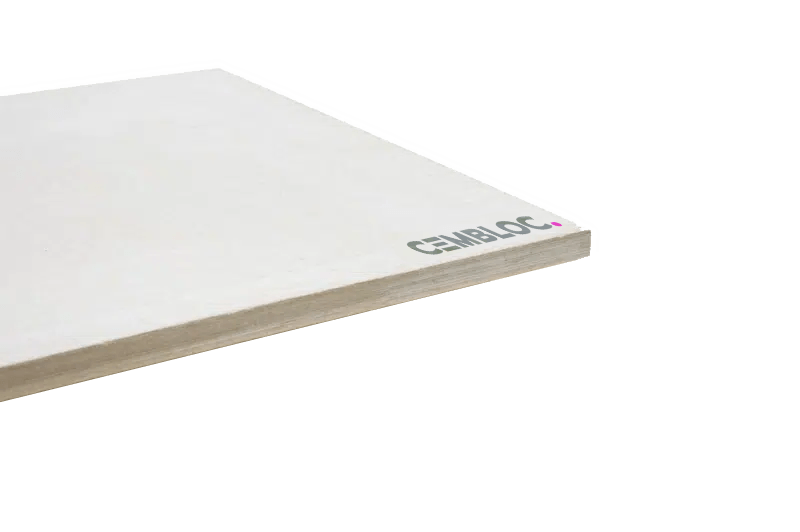

RENDER CARRIER / SHEATHING BOARD.

CemPlate® 6/9/12mm

Multi-purpose construction board/ Sheathing board/ Render Carrier Board

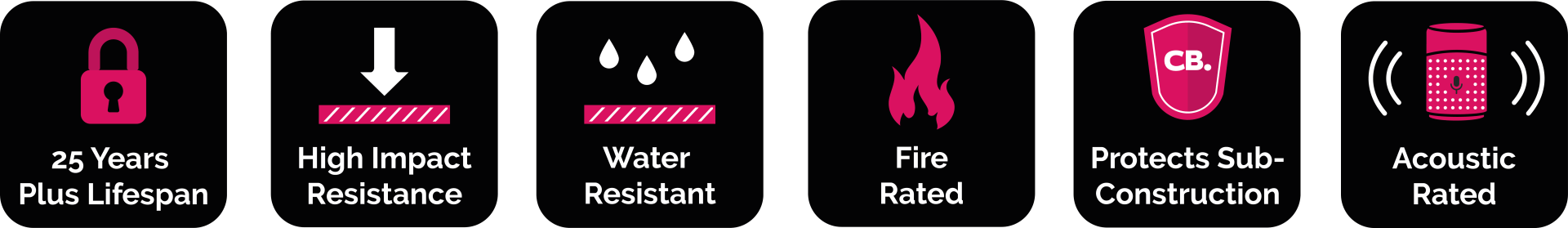

CemPlate® offers high levels of weather, moisture and fire resistance along with dimensional stability. Designed for modular builds, sheathing and as a render carrier.

Multi-purpose construction board/ Sheathing board/ Render Carrier

Description

The high-performing CEMBLOC® CemPlate® - The ultimate multi-purpose building board! With four major capabilities - weather protection, sound reduction (54db), render application (as a render carrier board), and fire protection - it's the perfect solution for all your building needs.

CemPlate® excels as a sheathing board, providing exceptional external weather protection*** for timber frame, modular, and steel frame (SFS) constructions prior to the installation of the finished external facade system. Its superior dimensional stability makes it an excellent choice for a render carrier board, enabling effective application of render finishes while ensuring a strong foundation for various surface treatments.

Choose CEMBLOC® CemPlate® for a reliable and versatile building board solution that meets the demands of modern construction. With its comprehensive capabilities and robust performance, CemPlate® is engineered to deliver exceptional results in a wide range of applications, from residential homes to commercial structures. Trust in CemPlate® for quality and peace of mind in your building projects.

CemPlate® also provides excellent sound insulation properties, reducing noise transmission up to 54 dB, making it an effective solution for residential and commercial applications where sound control is essential. While it contributes significantly to sound reduction, achieving optimal acoustic performance may require additional soundproofing measures depending on the specific building design and intended use.

| Product | SKU | Length | Width | Thickness | Weight | Edge Detail |

|---|---|---|---|---|---|---|

| CemPlate® Slimline 6 | CEM6005 | 2400mm | 1200mm | 6mm | 23.32kg | Flat Edge |

| CemPlate® 9mm | CEM6001 | 2400mm | 1200mm | 9mm | 35.0kg | Flat Edge |

| CemPlate® 12mm | CEM6002 | 2400mm | 1200mm | 12mm | 46.7kg | Flat Edge |

Support for Your Project

Have a technical advisor get in touch to discuss your needs and work out a suitable, effective solution for you. Get a quote, our experts are here to help you find the best solution for your project. Call us today:

+44 (0) 208 050 5302

or send an email to

support@cembloc.com

Used As A Render Carrier

CemPlate® can be used as a render carrier board which is becoming increasingly popular in the construction industry. CemPlate® is designed to provide a strong and durable substrate for rendering and cladding systems, making it the ideal choice for both indoor and outdoor applications.

CemPlate® is highly versatile and can be used as a substrate for a wide range of rendering and cladding systems. This makes it a great choice for projects where the design or aesthetic of the finished product is important.

In addition to its performance and versatility, CemPlate® is also a cost-effective option compared to other render carrier boards, making it accessible to a wide range of projects.

Approved Renders:

Advantages Of A Render Carrier Board?

- Provides durable protection for sub-construction systems, extending their lifespan.

- Resists dirt buildup, contributing to low-maintenance requirements.

- Manufactured without harmful substances and is environmentally friendly.

- Guaranteed asbestos-free for safe use in various environments.

- Classified as A1 for fire safety, meaning it is non-combustible.

- Does not emit toxic gases when exposed to fire.

- Highly resistant to moisture and water exposure, reducing risk of warping or swelling.

- UV-resistant, withstanding prolonged sunlight exposure with minimal degradation.

- Dimensionally stable, resisting cracking from seasonal temperature changes.

- Allows for straightforward installation and modifications.

- Can be precisely cut with suitable tools, such as carbide-tipped saws.

- Functions as a dry finishing material, eliminating the need for wet screed and associated drying times.

- Protects and extends the life of insulation materials in thermal and acoustic systems.

- Exhibits extremely high dimensional stability (<0.19%) compared to chipboard, gypsum, and cement particle boards.

- Moisture-resistant, effectively reducing water absorption compared to traditional wood and gypsum-based boards.

- Odourless and does not release toxic gases.

- Highly resistant to impact, making it suitable for high-traffic areas.

- Resistant to biological and chemical waste exposure, maintaining structural integrity.

- Lightweight and easy to transport.

- Insect-proof, non-putrescible, and resistant to mold growth.

- Versatile for a wide range of building applications.

- Compatible with insulation materials of any desired thickness.

- Provides smooth, precise cuts for fine detailing in installations.

- Offers very high impact resistance, significantly exceeding that of gypsum-based boards.

Areas Of Use.

- In suspended ceiling systems: Suitable for use in suspended ceiling applications, providing fire resistance and durability when installed according to guidelines and local building codes.

- Construction of fire walls: Effective as a component in fire wall construction, offering A1 fire-rated protection, provided it is installed following appropriate fire safety standards.

- In areas where sound insulation is required: Ideal for sound insulation applications, contributing to noise reduction in various environments; however, it may need to be combined with additional materials to achieve desired soundproofing levels.

- In thermal insulation systems: Functions as a part of thermal insulation systems, enhancing overall energy efficiency, but it should not be relied upon as the sole insulation material.

- Backer board for roof covering materials: Serves as a reliable backing material for various roof coverings, ensuring stability and protection when correctly installed to prevent moisture intrusion.

- As backing material for cabinets or panels: Suitable for use as a backing in cabinets and wall panels, providing structural support and moisture resistance; however, care should be taken to avoid excessive moisture exposure.

- On walls, parapets, and ceilings of balconies and terraces (non-exposed): Appropriate for covered areas of balconies and terraces, ensuring proper installation away from direct exposure to heavy moisture for long-lasting performance - otherwise 4-6 months uncovered if used with CEMBLOC CemClima tape.

- Steel column and fake column cladding: Ideal for cladding both structural and decorative columns, offering a consistent finish; proper installation is crucial for maintaining structural integrity.

- In external and internal render applications: Effective in both external and internal rendering, contributing to the building’s overall performance and appearance, but must be applied correctly to prevent moisture issues.

- On lift shaft walls: Suitable for installation on lift shaft walls, providing fire protection and durability when adhered to manufacturer specifications and local codes.

- Outbuilding wall cladding and roofing: Appropriate for cladding and roofing applications in outbuildings, ensuring protection against weather elements, but installation should account for potential moisture exposure.

- Construction site hoarding requiring additional fire protection. Can be used for construction site hoarding where enhanced fire protection is necessary; ensure compliance with safety regulations and standards during installation.

- In suspended ceiling systems: Suitable for use in suspended ceiling applications, providing fire resistance and durability when installed correctly.

- Construction of fire walls: Effective as a component in fire wall construction, offering A1 fire-rated protection when used in accordance with building regulations.

- In areas where sound insulation is required: Ideal for applications where sound insulation is desired, but may need to be combined with other materials for optimal performance.

- In thermal insulation systems: Functions as part of thermal insulation systems, enhancing energy efficiency, though it is not a primary insulator on its own.

- Backer board for roof covering materials: Serves as a reliable backing material for various roof coverings, ensuring stability and protection when installed correctly.

- As backing material for cabinets or panels: Suitable for use as a backing in cabinets and wall panels, providing structural support and moisture resistance.

- On walls, parapets, and ceilings of balconies and terraces: Appropriate for installation in covered areas of balconies and terraces; care should be taken to avoid direct exposure to heavy moisture.

- Soffit and fascia cladding: Can be effectively used for soffit and fascia applications, enhancing the aesthetic and protective features of buildings.

- Steel column and fake column cladding: Ideal for cladding both structural and decorative columns, offering a consistent finish when properly installed.

- In external and internal render applications: Effective in both external and internal rendering, contributing to the building’s performance and appearance, provided it is protected from extreme weather.

- On lift shaft walls: Suitable for installation on lift shaft walls, providing fire protection and durability when used according to design specifications.

- Outbuilding wall cladding and roofing: Appropriate for cladding and roofing applications in outbuildings, ensuring protection against weather elements.

- Construction site hoarding requiring additional fire protection: Can be used for construction site hoarding where enhanced fire protection is necessary, but installation must comply with safety regulations.

*** However, it's essential to limit exposure to weather conditions to no more than 4-6 months. Prolonged exposure can compromise the board's performance and integrity, so timely installation of the external facade is crucial to fully leverage the protective benefits of CemPlate®.

All Rights Reserved | CEMBLOC® (UK) acting under CEMBLOC® International