ULTIMATE TILE BACKER BOARD™

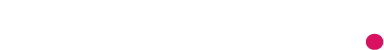

CemBacker® 6/12mm

Experience Unmatched Protection with CEMBLOC® CemBacker® - The Ultimate Tile Backer Board!

CemBacker® Offers Unbeatable Durability - The Impermeable, Waterproof Tile Backer Board System! With its UV stability and full weatherproofing, even in extreme temperatures, CemBacker® is the solution you need for a long-lasting and beautiful tiled finish.

Fibre cement tile backer board and plasterboard/ plywood replacement board

Description

Experience Unmatched Protection with CEMBLOC® CemBacker® - The Ultimate Tile Backer Board! Designed to provide fireproof and waterproof protection for tiled walls (1200 x 600 x 12mm) and floors (1200 x 600 x 6mm), CemBacker® is the solution you need to keep your tiled rooms safe and secure.

Get the Best of the Best with CemBacker® - Tested by the Leading Companies! With rigorous testing by market-leading tile adhesive companies and the largest manufacturer of ceramic and porcelain tiles in the world, CemBacker® sets the bar for high standards acting as one of the best tile backer boards. With an impressive strength of 105kg/m², it can support the heaviest tiles available on the market.

Say Goodbye to Deterioration with CemBacker® - The Superior Tile Backer Board Panel! Outperforming traditional methods like plasterboard and plywood, CemBacker® offers exceptional moisture and fire resistance along with dimensional stability, making it the perfect solution for wet rooms but also wall lining proving up to 51 db airborne rating.

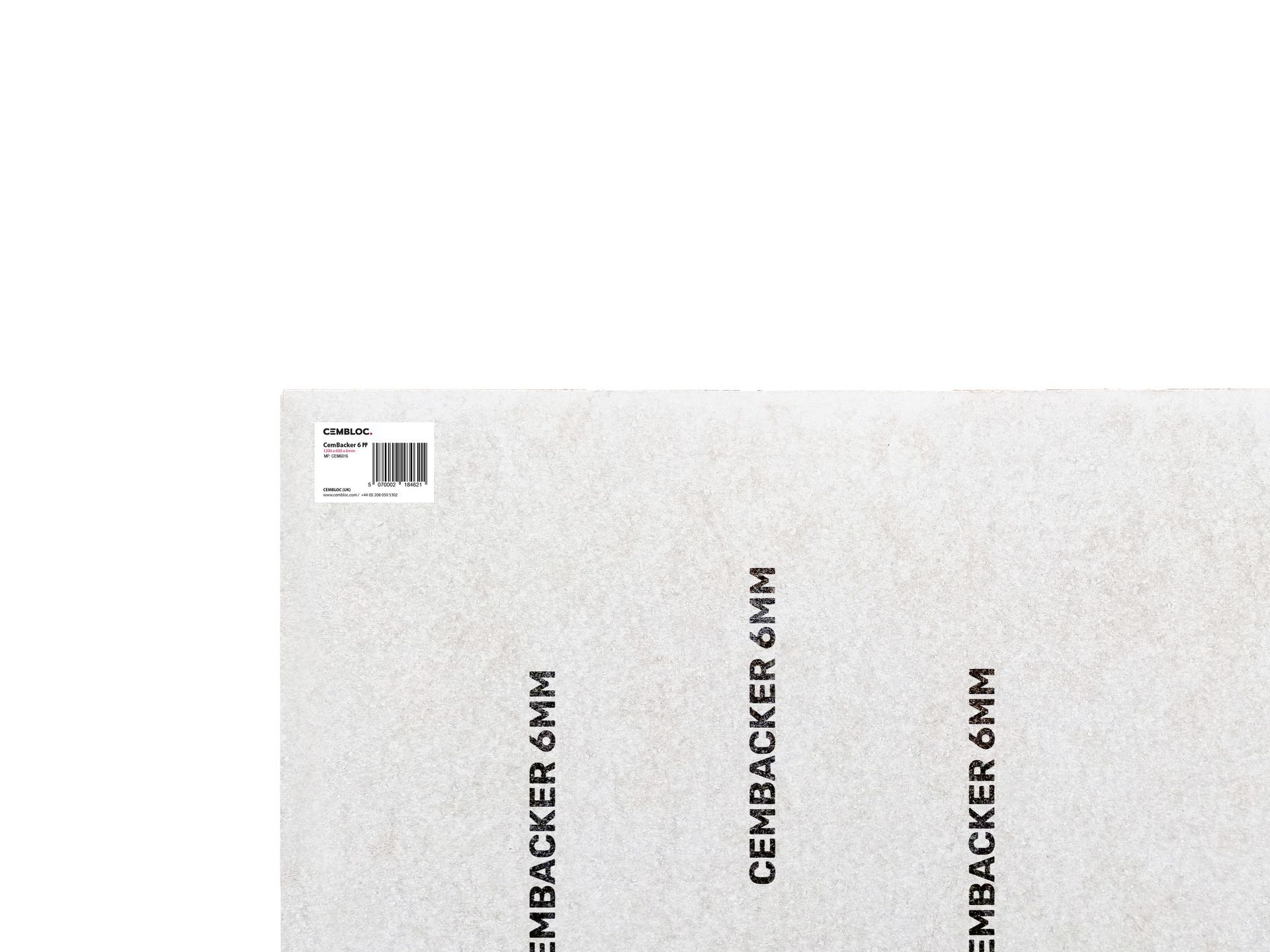

Stay Safe and Secure with CemBacker® - The Non-Combustible, A1 Fire Rated Solution! With its resistance to water, non-combustibility, and A1 fire rating, CemBacker® is the safe and secure choice for your tiling projects.

Enjoy Unbeatable Durability with CemBacker® - The Impermeable Tile Backing System! With its UV stability. CemBacker is the solution you need for a long-lasting and beautiful tiled finish.

Choose the Ultimate Tile Backer Board with CEMBLOC® CemBacker®

CemBacker® is designed to be highly water-resistant and has an A1 fire rating, making it a reliable tile backing solution. It can withstand freezing temperatures and is resistant to UV light, ensuring durability in various conditions. While it is suitable for wet room applications, it is important to ensure proper installation and protection against direct, prolonged exposure to heavy moisture for optimal performance especially in external tiling applications.

Now Available: CemBacker® PrePrimed – Ready to Use with Less Hassle! Take your tiling projects to the next level with CemBacker® PrePrimed, a factory-primed version designed for faster installation, reduced dust, and superior adhesion. PrePrimed eliminates the need for on-site priming, saving time while ensuring a consistent, high-quality surface for tile adhesive. With less dust during cutting and handling, it provides a cleaner, safer working environment, making it ideal for both professional installers and DIY users, with the added convenience of a pre-primed surface.

Our professional team are here to help you with any questions.

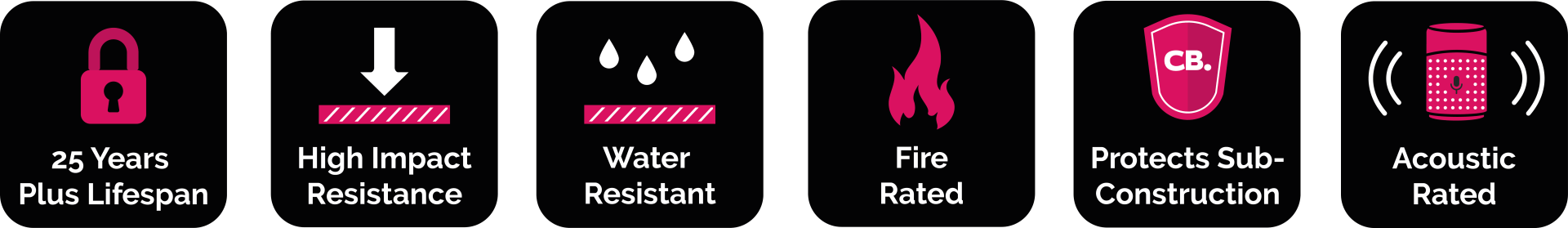

Key Features

Standard Sizes

Thicknesses: 6mm (for floors), 12mm (for walls)

Dimensions: 1200mm x 600mm

Fire Performance

A1 Fire Class

Max Tile Holding

105kg/m2

Acoustic Rating (DnTw)

Superior sound insulation credentials for a wall built using CemBacker®12 in conjunction with a Acuphon's PhonoClip® system, furring bars and high density mineral fibre; ranges between 46 db and 51 db.

| Product | SKU | Colour | Length | Width | Thickness | Weight | Edge Detail | Qty Pallet |

|---|---|---|---|---|---|---|---|---|

| CemBacker® 6mm | CEM6003 | Grey | 1200mm | 600mm | 6mm | 5.83kg | Flat Edge | 150 |

| CemBacker® 12mm | CEM6004 | Grey | 1200mm | 600mm | 12mm | 11.66kg | Flat Edge | 82 |

| CemBacker® PrePrimed 6mm | CEM6016 | White | 1200mm | 600mm | 6mm | 5.97kg | Flat Edge | 150 |

| CemBacker® PrePrimed 12mm | CEM6017 | White | 1200mm | 600mm | 12mm | 11.81kg | Flat Edge | 82 |

Innovative Fibre Cement Solutions by CEMBLOC®

Relevant Ancillaries For CemBacker 6mm and 12mm)

Support for Your Project

Have a technical advisor get in touch to discuss your needs and work out a suitable, effective solution for you. Get a quote, our experts are here to help you find the best solution for your project. Call us today:

+44 (0) 208 050 5302

or send an email to

support@cembloc.com

Advantages Of Use.

- Provides durable protection for sub-construction systems, extending their lifespan.

- Resists dirt buildup, contributing to low-maintenance requirements.

- Manufactured without harmful substances and is environmentally friendly.

- Guaranteed asbestos-free for safe use in various environments.

- Classified as A1 for fire safety, meaning it is non-combustible.

- Does not emit toxic gases when exposed to fire.

- Highly resistant to moisture and water exposure, reducing risk of warping or swelling.

- UV-resistant, withstanding prolonged sunlight exposure with minimal degradation.

- Dimensionally stable, resisting cracking from seasonal temperature changes.

- Allows for straightforward installation and modifications.

- Can be precisely cut with suitable tools, such as carbide-tipped saws.

- Functions as a dry finishing material, eliminating the need for wet screed and associated drying times.

- Protects and extends the life of insulation materials in thermal and acoustic systems.

- Exhibits extremely high dimensional stability (<0.19%) compared to chipboard, gypsum, and cement particle boards.

- Moisture-resistant, effectively reducing water absorption compared to traditional wood and gypsum-based boards.

- Odourless and does not release toxic gases.

- Highly resistant to impact, making it suitable for high-traffic areas.

- Resistant to biological and chemical waste exposure, maintaining structural integrity.

- Lightweight and easy to transport.

- Insect-proof, non-putrescible, and resistant to mold growth.

- Versatile for a wide range of building applications.

- Compatible with insulation materials of any desired thickness.

- Provides smooth, precise cuts for fine detailing in installations.

- Offers very high impact resistance, significantly exceeding that of gypsum-based boards.

Areas Of Use.

- Tile backer boards for use behind ceramic tiles in wet-room areas: Excellent choice for wet-room applications, providing a moisture-resistant backing that supports tile installation.

- Perfect for ‘Ready Wall Panel’ systems: Compatible with ‘Ready Wall Panel’ systems, contributing to quick and efficient construction.

- For use as a wall finish: Suitable as a wall finish, offering durability and aesthetic flexibility for various interior and exterior applications.

- Ideal for use on pre-fabricated buildings: Well-suited for pre-fabricated building applications, providing structural integrity and weather resistance.

- As a finishing material that can be painted: Functions as a finishing material that can be easily painted, allowing for customization in design.

- Ideal for sheds: A practical option for sheds, offering protection against moisture and ensuring longevity in outdoor environments.

- In areas where sound insulation is required: Suitable for use as part of a sound insulation system due to their density and mass, often combined with additional insulation materials for optimal performance.

- In thermal insulation systems: Functions as a protective layer within thermal insulation systems, though not as a primary insulator on its own.

- As backing material for cabinets or panels: Ideal for use as a backing material in cabinets and wall panels, providing durability, fire resistance, and moisture protection.

- On walls, parapets, and ceilings of balconies and terraces (non-exposed): Appropriate for covered areas of balconies and terraces, ensuring proper installation away from direct exposure to heavy moisture for long-lasting performance - otherwise 4-6 months uncovered if used with CEMBLOC CemClima tape

Downloads